Products

Get the BEST Tools and Materials for Making Concrete Countertops Here!

Free Training

View Our MASSIVE Collection of Free Concrete Countertop Training!

Hands-on Training

Ready to go PRO? Build a Successful Concrete Countertop Business

CCI ALUMNI EVENT, ORLANDO, FL

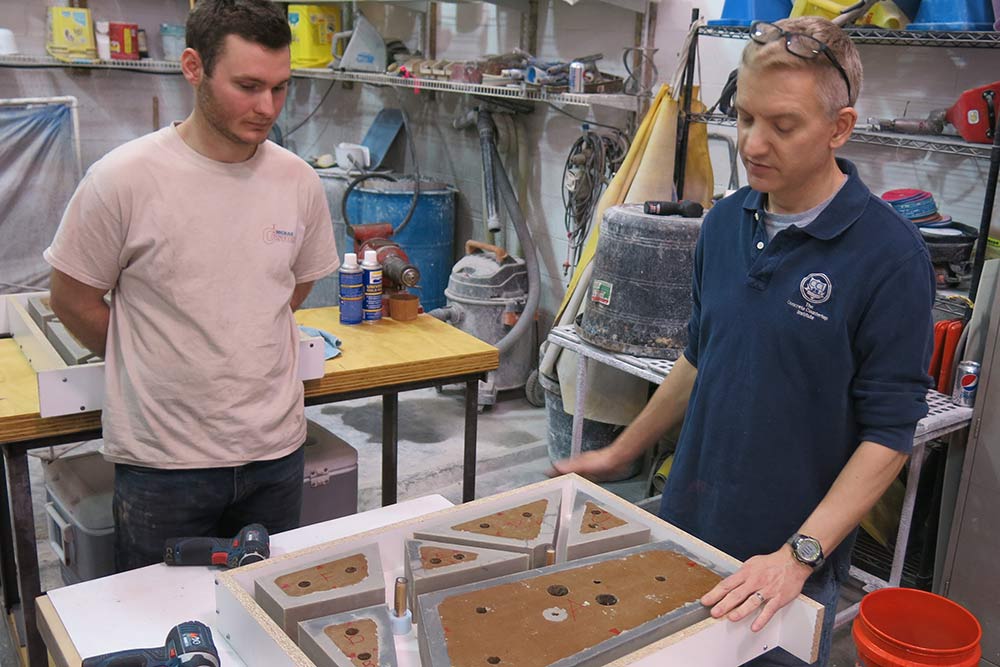

Twenty CCI alumni recently converged on the shop of alumnus Caleb Lawson of Price Concrete Studio in Orlando…

BRENT INDENBOSCH, BC, CANADA

When you make massive custom concrete creations like Brent does, sometimes delivery is the trickiest part!…

JUSTIN MCRAE, ATHENS, GA

“I still can’t believe how many doors have opened since training with CCI – cashed in my savings bonds (thanks Grandma) drove to…

Frequently Asked Questions About Concrete Countertops

If you are a homeowner considering concrete countertops for your kitchen or bathroom, here is some basic information about the most frequent questions and misconceptions about concrete.

High quality concrete will give you a beautiful, smooth and durable surface that you will love, and that is easy to clean and care for.

Are concrete countertops less expensive than granite?

If you are looking to purchase professionally made concrete countertops: No, absolutely not! If they are, you should be wary of having a sidewalk on top of your cabinets.

High quality concrete countertops are hand crafted by skilled artisans using ultra high performance concrete mixes and sealers. They are hand made, custom, unique and personalized – and worth the money.

How much does it cost to make concrete countertops?

DIY Concrete Countertops

A few hundred dollars. Click here.

Pro Concrete Countertops

If you are a professional looking to make concrete countertops as a business, material costs of concrete countertop mixes are not the issue. Concrete is mainly sand, cement and water, with some admixtures and fibers added in.

The important thing for pros is knowledge about and skill in concrete, plus all of the other processes: templating, forming, reinforcing, diamond polishing, sealing, installation. Labor is by far a bigger cost in creating concrete countertops than materials are.

Even more important is business management. For creative concrete professionals, The Concrete Countertop Institute provides extensive business training and resources, in addition to technical training on concrete and hands-on learning, in The Ultimate Creative Concrete Training.

Are concrete countertops durable?

Yes, when properly made. “Durable” could refer to structural integrity, or to appearance. High quality concrete countertops should have both types of durability.

You may have heard the maxim, “Concrete cracks”. You’ve seen huge cracks in sidewalks. This does not have to be the case with concrete countertops. Tiny hairline cracks are possible, but structural cracks should never occur in properly made concrete countertops.

The durability of the appearance of your concrete countertops depends entirely on how they are sealed. Bare concrete is porous and highly susceptible to staining. Acids literally eat away the cement paste between the sand grains in bare concrete.

But if a high performance coating sealer such as Omega or Ovation is applied, acids and staining agents will never touch the concrete. Your concrete will still look very natural, and it will not require maintenance.

How often do you have to paint your car?

How often do I need to reseal my concrete countertops? How do I maintain them?

The answer to this question depends entirely on the sealer used.

Cheap acrylic sealer will need maintenance every few months, maintenance of penetrating treatments will vary, whereas a high performance coating such as Omega or Ovation will never need to reapplied unless abused.

All sealed concrete surfaces should be cleaned with a non-abrasive cleaner. Coating sealers should never be cut on. Unless your coating is made of diamonds, it will scratch!

How thick should a concrete countertop be?

There is no need for precast concrete countertops to be thicker (and heavier!) than typical countertops such as granite and solid surface.

With high performance concrete countertop mixes and proper reinforcing, GFRC concrete countertops are made 3/4″ (19 mm) thick, and the edges are turned down to achieve the desired appearance of thickness.

Traditional steel-reinforced precast concrete countertops can be made 1.5″ (38 mm) thick.

How heavy are concrete countertops? Do I need to reinforce my cabinets?

Concrete is about the same weight of stone of the same thickness. 1.5″ thick precast concrete countertops weigh about 18 pounds per square foot, whereas granite countertops typically weigh about 19 pounds per square foot.

You don’t think twice about putting granite on cabinets without extra reinforcement, so why would you need it with concrete?

GFRC concrete countertops are generally made only 3/4″ thick, half the thickness of traditional countertops, so they weigh about half as much.