Aggregate in precast concrete is a structural filler, but its role is more important than what that simple statement implies. Aggregate occupies most of the volume of the concrete. It is the stuff that the cement paste coats and binds together. The composition, shape, and size of the aggregate all have significant impact on the workability, durability, strength, weight, and shrinkage of the concrete. Aggregate can also influence the appearance of the cast surface, which is an especially important consideration in precast concrete countertop mixes.

(Note that GFRC concrete mixes are different. They are all-sand mixes, and the gradation requirements are completely different. For more information about GFRC mix design, click here.)

When selecting the most appropriate aggregate for a precast concrete countertop mix, here are the key factors to consider:

Material

Most natural stones and crushed rock are appropriate for use in concrete. Commonly used stones are quartz, basalt, granite, marble, and limestone. If a concrete countertop is going to be ground with diamond tooling, the aggregate will show, so aesthetics also affect the choice of aggregates.

Problems arise with soft, reactive or weak stone or rock. Lightweight aggregates, a topic for another discussion, are also used in concrete.

Size

Aggregate size and gradation are the most important factors when selecting aggregate. Aggregate can be large or small, from fist-sized rocks to fine sand. Aggregates larger than ¼ inch are classified as coarse aggregate, while anything smaller than ¼ inch is termed fine aggregate. As a general rule, the largest aggregate should be no greater in diameter than one-third the depth of the slab, or one-fifth the smallest dimension of the form. For example, the largest piece of aggregate allowed for a 1 ½-inch-thick countertop slab is ½ inch. Generally coarse aggregate is blended with finer aggregates (such as sand) to fill in the spaces left between the large pieces and to “lock” the larger pieces together. This reduces the amount of cement paste required and decreases the amount of shrinkage that could occur.

Shape

Aggregate shape influences strength, but has more of an immediate impact on the workability of the plastic concrete. Rough, angular particles pack tighter, have more surface area, and have greater interparticle friction than smooth, rounded particles, which reduces workability. Angular particles also require a bit more cement paste to coat them than rounded particles. Therefore, mixes containing them will require a slightly higher cementitious content.

Gradation

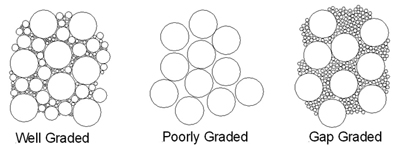

In general, coarse aggregates tend to be about 10 times larger than the fine aggregates in concrete, but the range of sizes could be greater than that in certain circumstances. As shown in the figure, there are three typical range categories:

- Well-graded aggregate has a gradation of particle sizes that fairly evenly spans the size from the finest to the coarsest. A slice of a core of well-graded aggregate concrete shows a packed field of many different particle sizes.

- Poorly graded aggregate is characterized by small variations in size. This means that the particles pack together, leaving relatively large voids in the concrete.

- Gap-graded aggregate consists of coarse aggregate particles that are similar in size but significantly different in size from the fine aggregate. A core slice of gap-graded concrete shows a field of fine aggregate interspersed with slightly isolated, large aggregate pieces embedded in the fine aggregate.

Typical aggregate gradations are shown in the drawing below:

Poorly graded concretes generally require excessive amounts of cement paste to fill the voids, making them uneconomical. Gap-graded concretes fall in between well-graded and poorly graded in terms of performance and economy. Gap-graded concrete is a viable gradation, but not optimal.

Well-graded aggregates are tricky to proportion. The goal of aggregate proportioning and sizing is to maximize the volume of aggregate in the concrete (and thus minimize the volume of cement paste) while preserving strength, workability, and aesthetics. This balances the proportions of each so there are just enough of each size to fill all the voids, while preserving workability and cast-surface quality.

Note that aggregate gradation is particularly important in cast in place concrete countertop mixes. This article explains further about cast in place mixes.

Mortar Concrete

Concrete made with just fine aggregate (or sand) is known as mortar concrete. Like the mortar used for brick and concrete block construction, which is simply made with mortar cement and sand, mortar concrete has no coarse aggregate in it, so a ground finish will have a fine-grained appearance. Mortar concrete is commonly used in precast concrete countertop mixes, since the surface finish is so important.

Even with an all-sand mix, aggregate gradation is still an important factor to consider and affects strength, workability, and aesthetics. It is always preferable to have some particle size variation rather than absolute uniformity because the interparticle void volume will be lower than with uniform particle sizes. While it is possible to blend different sands of different sizes together in a fashion similar to graded aggregates, generally only one type of sand is used. Most sand, especially bulk or bank-run sand, already has a particle size distribution that has some variation to it.

In order to achieve adequate workability, the cement paste volume must be high enough to encapsulate all of the aggregate particles and to provide some workability while the concrete is fresh. Therefore, mortar concrete tends to have a high cement content.

Conclusion

Aggregate gradation, whether in a mortar concrete or a traditional concrete mix, involves tradeoffs between strength and workability and is always a delicate balance. Understanding the implications of aggregate gradation is especially important when creating a from-scratch mix and will ultimately help you produce a better precast concrete countertop.

For an exact mix design for precast concrete countertops, click here. For an exact mix design for GFRC concrete countertops, click here.